QD-60T螺絲包裝機

第一節(jié):產(chǎn)品介紹和總體共同點:

QD-60T3多振盤拖斗五金零件專用包裝機,根據(jù)貴公司的產(chǎn)品,用多個不同的振盤完成自動記數(shù)及下料,袋子寬度 mm(暫定尺寸,以實物為準),包裝膜的寬度:240mm,袋長220mm(視物料定、長度可以調(diào)節(jié)),考慮到袋子的寬度及產(chǎn)品的特殊性,我公司建議主機使用QD-60T4多振盤拖斗五金零件專用包裝機。希望我們的方案和建議能夠滿足您的要求。

總體特點:

1.高質(zhì)量的包裝和績效產(chǎn)品的損耗;

2.包裝外觀—有成熟的技術(shù)保證;

3.讓客戶的產(chǎn)品在短時期內(nèi)得到快速、精確、衛(wèi)生的完美包裝;

4.系統(tǒng)的設(shè)計能滿足您特殊的要求。

需包裝物料明細:見實物

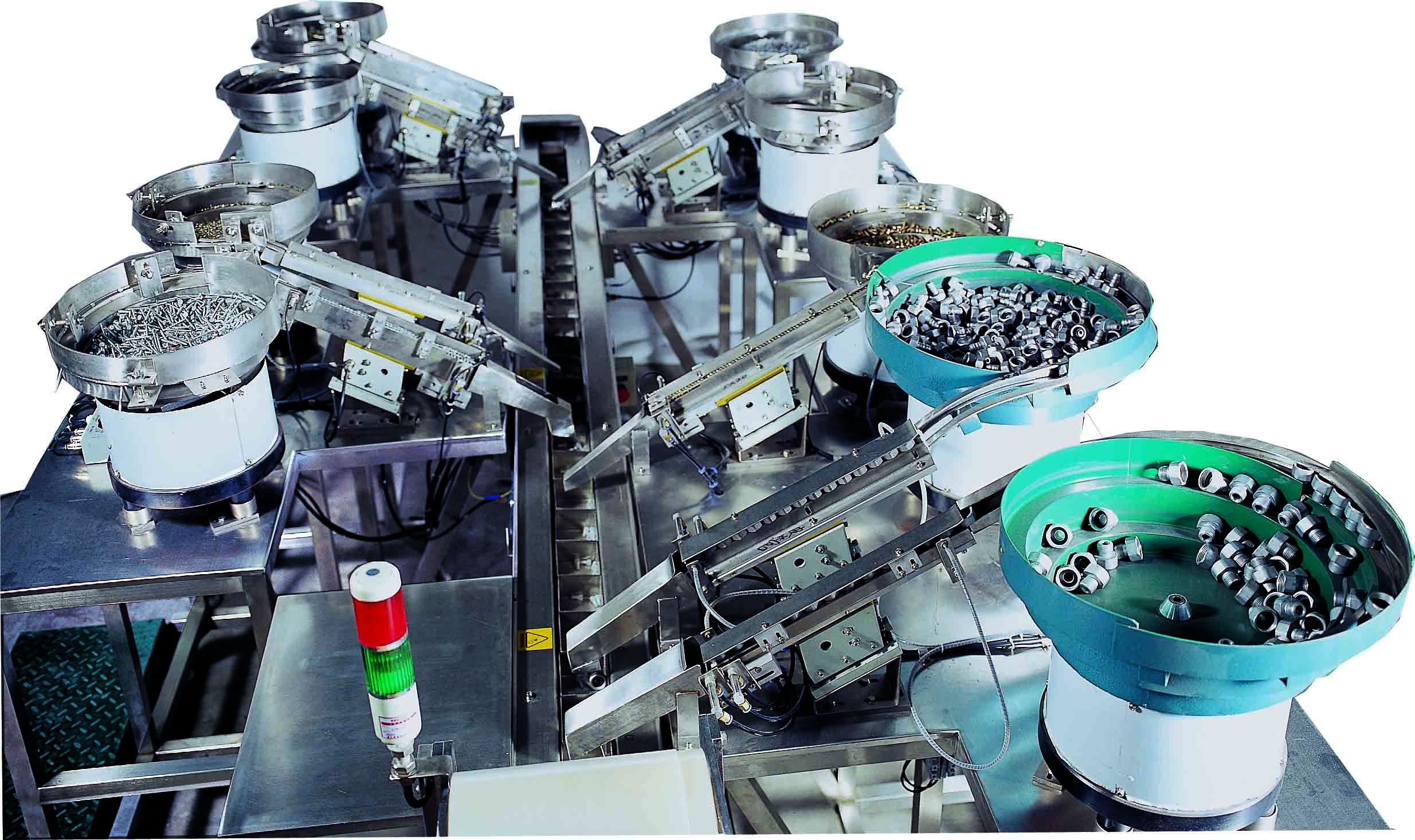

A類似機器正側(cè)面圖片:

B機器正面圖片:

C機器自動給料盤分布圖片:

D包裝樣袋圖片:

第二節(jié):用戶規(guī)格:

1)包裝材料:包裝材料:OPP/CPP,CPP/PE等可熱復(fù)合材料;要求成卷使用≤300建議使用BOPP熱封膜。

2)包裝產(chǎn)品:3種五金產(chǎn)品(按樣品和方案中的約定).

3)包裝要求:盡量能達到通用使用性能及能準確無誤。

4)生產(chǎn)能力:15-40(袋/分)

5)制袋尺寸:長 毫米,寬 毫米。(視實際物料設(shè)計袋子的大小)自動顯示包裝數(shù)量。設(shè)備出現(xiàn)故障自動停機、自動報警。(安裝提示信號燈)。

6)振動盤共9個,各振動盤可單獨開關(guān)、單獨使用,各振動盤下料數(shù)可單獨調(diào)節(jié)數(shù)量(螺絲調(diào)節(jié)數(shù)量在1-8個、五金配件調(diào)節(jié)數(shù)量建議人工投)。

7)具體組合為:每4個振盤合為一組、如有人工投料的位置留在主機后面(能更好的檢閱設(shè)備及給料系統(tǒng)的給料狀態(tài))

自動計數(shù)系統(tǒng)采用進口光纖或合資氣動元件。

8)振動盤放置臺:總體框架:采用40*40*20碳鋼;臺面采用T=8mm鋼板噴漆;;腳杯采用M16螺釘鍍鋅杯。

9)整機外包不銹鋼材料、輸送鏈盒采用T=1.0 201不銹鋼制作。

10)供紙部分結(jié)構(gòu)外表鍍鉻。

機械總體名稱:氣動式多振盤包裝機(背封)

第四節(jié):產(chǎn)品參數(shù)介紹及說明:

主要技術(shù)參數(shù):

|

包裝速度 |

15-40袋/分鐘 |

|

計量范圍 |

螺絲1-8顆 |

|

制袋長度 |

30-2200mm 可以自動調(diào)節(jié) |

|

制袋寬度 |

50-110mm 更換成型器可以改變制袋大小 |

|

制袋方式 |

背封直紋封合 |

|

工作電源電壓 |

220V、50HZ單相 |

|

設(shè)備最大外形尺寸 |

約長4600*1800*1650MM |

1、送料順暢、運行平穩(wěn)、噪音低,不損傷原料,操作調(diào)整簡單,易懂。送料計數(shù)準確,不漏料、多料、卡料等現(xiàn)象。

2、設(shè)備系統(tǒng)基本動作具有手動切換功能、自診功能,當出現(xiàn)故障后能夠自動停機報警,急停按鈕應(yīng)安裝在容易操作的地方,以方便員工操作。

3、設(shè)備需具有封口牢固、密封性好、袋型平整、精美,包裝效率高堅固耐用,震動輕微,故障率低于,出現(xiàn)不良時自動停機、自動報警,壽命長等特點。

4、該設(shè)備能實現(xiàn)自動完成分揀、計量、填充、裝包、計數(shù)等工作。螺絲包裝顆數(shù)1-8粒隨意調(diào)節(jié),自動顯示包裝數(shù)量,可方便的統(tǒng)計出機器的工作量。

5、設(shè)備需具有高度的安全防護功能(各危險部位均需安裝安全保護裝置)

6、本機需具有無料、缺料自動檢測,缺料、無料時設(shè)備會自動停機報警,設(shè)備中每個送料器可任意開啟或關(guān)閉,以方便生產(chǎn)需要。

7、設(shè)備說明書、圖紙和操作維修手冊等文本以中文為準,設(shè)備需設(shè)計得小巧,外形美觀,人性化設(shè)計。

8、采用PLC控制系統(tǒng),故障自停機、自報警、自診斷、使用安全,并設(shè)有中文人機操作界面,從而使設(shè)備操作簡單,調(diào)整方便,自動化程度高。

9、操作維修方便:間歇式結(jié)構(gòu)簡單,易于操作和維修,通用性強。

Snack food Counting and Packaging Machine

A snack food counting and packaging machine is a specialized piece of equipment used to accurately count and package individual snack food items, such as chips, candies, nuts, and other similar products. This machine automates the process of counting and packaging, significantly improving efficiency and reducing human error.

Here are some key features and functions of a snack food counting and packaging machine:

- Accurate Counting: The machine is equipped with sensors and counting mechanisms that can accurately count the number of snack food items. This ensures that each package contains the correct quantity of product, satisfying customer expectations and maintaining brand consistency.

- Flexible Packaging Options: Snack food packaging machines are designed to handle a variety of packaging materials and formats, including bags, pouches, cartons, and more. They can also adjust the packaging size and shape based on the product and packaging requirements.

- Automated Packaging Process: The machine performs the entire packaging process automatically, from counting the snack food items to filling the packaging material, sealing it, and often even applying labels or printing information on the package. This reduces the need for manual labor and speeds up the packaging process.

- Adjustable Speed and Capacity: Snack food counting and packaging machines are typically designed with adjustable speed and capacity settings. This allows manufacturers to adjust the machine's output based on production demands, ensuring efficient use of resources and meeting production targets.

- Easy to Operate and Maintain: These machines are designed with user-friendly interfaces and controls, making them easy to operate even for non-technical personnel. Additionally, they often feature modular designs and replaceable parts, simplifying maintenance and reducing downtime.

- Compliance with Industry Standards: Snack food counting and packaging machines comply with relevant industry standards and regulations, ensuring that the packaged products meet food safety and quality requirements.

By using a snack food counting and packaging machine, manufacturers can significantly improve their production efficiency, reduce costs, and maintain consistent product quality. This helps them meet market demands, enhance customer satisfaction, and compete effectively in the snack food industry.

在線客服

在線客服